CRAFT Tech performed steam quenching simulations for the NASA B-2 spray chamber to support facility design modification and test planning. CRAFT CFD multi-phase models for droplet transport and phase change were utilized to predict the effectiveness of various spray conditions and configurations to quench the exhaust steam from a J-2X rocket motor and control chamber pressure.

CRAFT CFD features physics-based methodology for incorporating the effects of evaporation and condensation within a disperse multi-phase, multi-species CFD framework. The coupled Eulerian particulate and gas phase flow solver utilizes the Hertz-Knudsen formulation for exchanges in mass, momentum, and enthalpy based on calculated partial pressure of the condensable gas specie, surface tension, droplet diameter, and gas and droplet temperatures. The approach has been applied to modeling flowfield conditions persisting within the NASA Plum Brook B-2 spray chamber facility during high-altitude rocket fire tests of both 20,000-lbf and 300,000-lbf class motors.

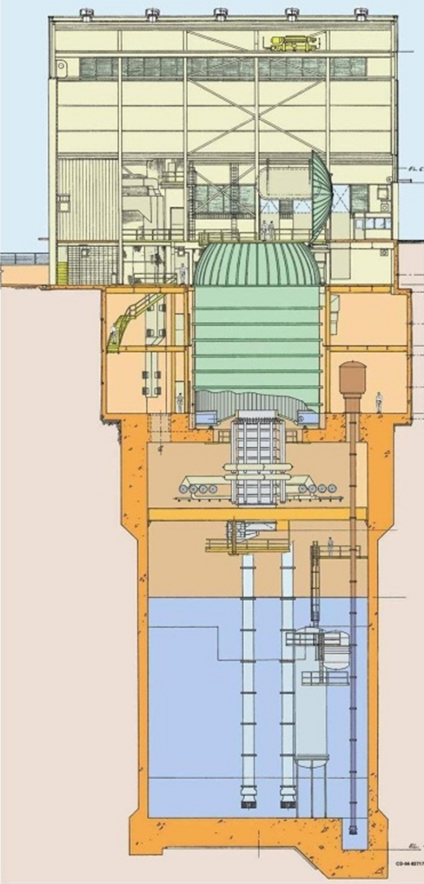

Transient Simulation